Facade Systems

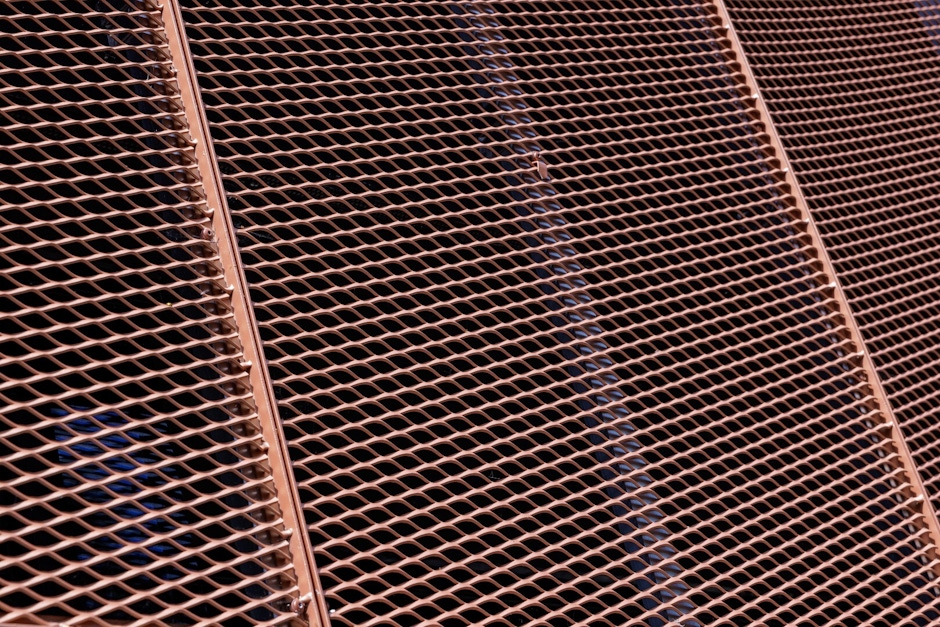

Anvil Expanded Mesh Cladding

Expanded Mesh

Anvil expanded mesh cladding is a range of expanded metal profiles that can be produced with a frame round the outside of the panel size and fitted back to a helping hand or floor-to-floor framing system to be used as a rainscreen facade. Expanded metal mesh not only provides striking visual effects, but several practical functions such as enhanced air flow, increased security and shading.

We offer 13 standard expanded patterns and bespoke options can be discussed and developed with our team to suit project requirements. The range of 13 standard patterns are all supported by engineered calculations, bracket spacings and spanning distances.

Product details

Colours and Finishes

Expended mesh can be used internally and externally as rainscreen panels or as feature panels, in a variety of colours and finishes. Finishes include A2 fire-rated PPC paint, A1 fire-rated anodised or selected natural metal. If you have an example of the colour or finish you are looking to achieve, send this across to us and we will work with you to design the optimum solution.

Design

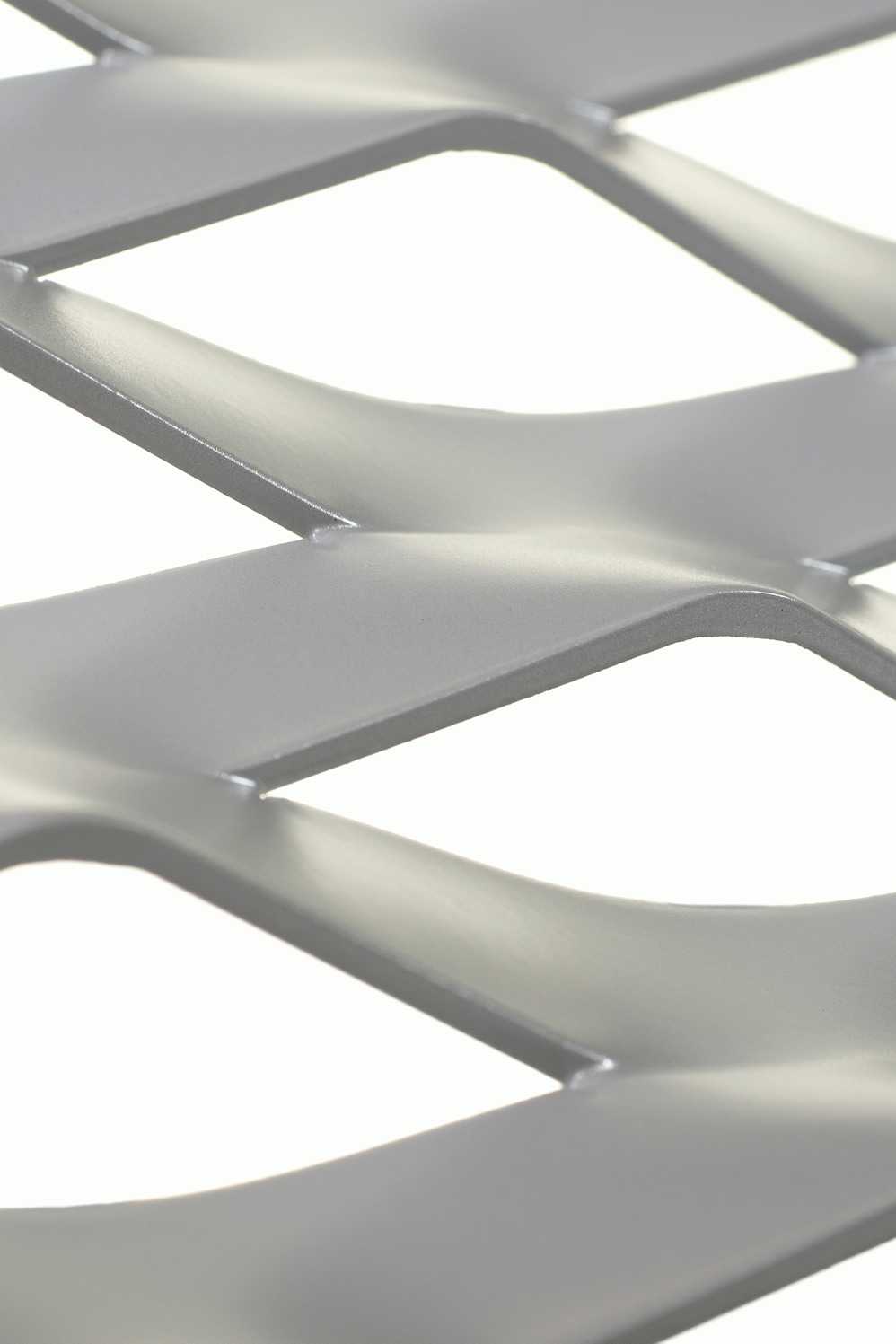

The quantity and size of the 'eyes' of the expanded mesh, are a critical factor for consideration in the design process. The design of the mesh pattern ultimately depends on the shape of the tool utilised in the expansion or perforation process. The shape may be square, diamond or hexagonal, and each eyelet has its own visual features for use in design and architecture.

Patterns can be bordered, curved and folded and easily adapted to suit most applications or easily combine with other materials such as facing brickwork, glass or wrought iron. Expanded mesh screens are extremely strong and flexible enough to be used for metalwork fabrication and metal structures. Our team can provide advice and guidance to assist you in selecting the appropriate format of expanded mesh panel.

Sustainability

The intrinsic structure of mesh panels (being a single piece) means they offer a sustainable product choice, as during manufacturing, there is very little waste. Slitting and stretching is used to create holes as opposed to being punched out, resulting in less raw material waste, As well as having a long working life due to their robust nature, at the end of their usage, expanded mesh can be easily disposed of and is 100% recyclable.

We work with responsible manufacturers who are accredited to ISO 4001:2004 and ISO 9001:2008. For more information, please get in touch.

Resources

Be inspired

More facade systems

Visit our showrooms

Speak to our team

To speak to one of our team, call us on 0203 794 9377 or email enquiries@taylor.maxwell.co.uk

Contact our team